150 ANTI-ROLL DEVICES FOR SHIPS

small, the initial current through the motor and magnetic brake is large. The brake is completely released, the motor starts very quickly and the stabilizing gyro-axle moves about the athwartship axis with high angular acceleration in the same direction as the precession due to the torque produced by the ship's roll. The magnitude of the angular acceleration depends upon the design of the motor and attached apparatus. About one-half second is required for the control gyro to operate and about one second for the precession motor to acquire full speed.

While the precession motor is gaining in speed, the back electromotive force increases in value, thereby reducing the current in the motor and in the magnetic brake. When the precessional speed of the spin-axle of the stabilizing gyro has the required value, it is maintained practically constant for the required length of time by allowing the proper amount of current to traverse the brake coils.

After the stabilizing gyro-axle has precessed to near the end of its swing, the brake effect is suddenly increased, thereby bringing the precessional speed to zero when the gyro-axle has made the specified maximum displacement from the central position. At this instant nearly one-half period should have elapsed since the spinaxle of the stabilizing gyro was in the central position

When the vessel starts to roll in the opposite direction, the spinaxle of the control gyro precesses in the opposite direction, thereby making an electric contact which causes the precession motor to rotate in the direction opposite to its previous rotation. The same succession of actions above described is now repeated.

The spin-axle of the stabilizing gyro moves back and forth in opposite phase to the velocity of the ship's roll even though the period of roll is not constant. Nearly all the energy that would exhibit itself in the roll of the ship is converted into heat, and the roll is quenched soon after its inception. If any single wave would produce a roll less than that which the stabilizer can prevent, then the control gyro automatically reduces the arc of precession and stops the precession as soon as this single roll has been neutralized. On the other hand, if any single wave would produce a roll greater than that which the stabilizer can neutralize, then the ship will roll through a diminished angle. If the succeeding waves are small, the roll will be entirely quenched

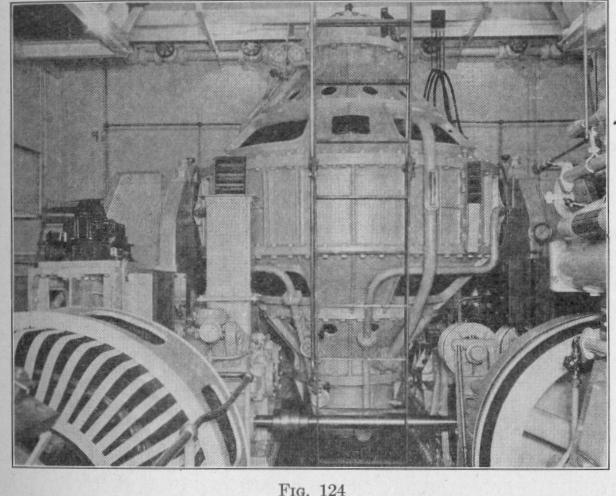

The complete stabilizer equipment of the Sperry active type installed in a large yacht is represented in Fig. 124. It weighs

THE ACTIVE TYPE OF GYRO SHIP STABILIZER 151

about 3 per cent as much as the ship. The Japanese 10,000-ton airplane carrier, Hosho, the 2000-ton Italian flotilla leader, Pigafetta, and many yachts of various sizes up to 5500 tons are stabilized by similar equipments. The stabilizer for a yacht costs in the neighborhood of one-fortieth as much as the yacht. The largest ship stabilizer ever built is on the Lloyd Sebaudo liner, Conte di Savoia. The ship has a displacement of 45,000 tons, metacentric height of 2.2 feet, and period of roll of about 24 sec

onds. The stabilizer consists of three complete units each having a main gyro of 215,000 pounds, diameter 13 feet, moment of inertia 4,700,000 pound-feet', and speed of 910 revolutions per minute. The entire equipment has a weight of about 624 tons and cost about $700,000. It will prevent the roll of the ship exceeding three degrees from its upright position.

95. The Braking System. - This is a highly important part of any ship stabilizer. The system used in the Sperry active type now will be briefly described. Rolling of the ship produces on the stabilizing gyro a torque that is proportional to the spin velocity of the gyro and the angle of roll of the ship at the given instant,